Quality is the lifeline of the Mold Processing Center, supported by a rigorous, interconnected quality management system:

Raw materials are strictly selected to meet the specific requirements of silicone/rubber molds, eliminating any substandard inputs.

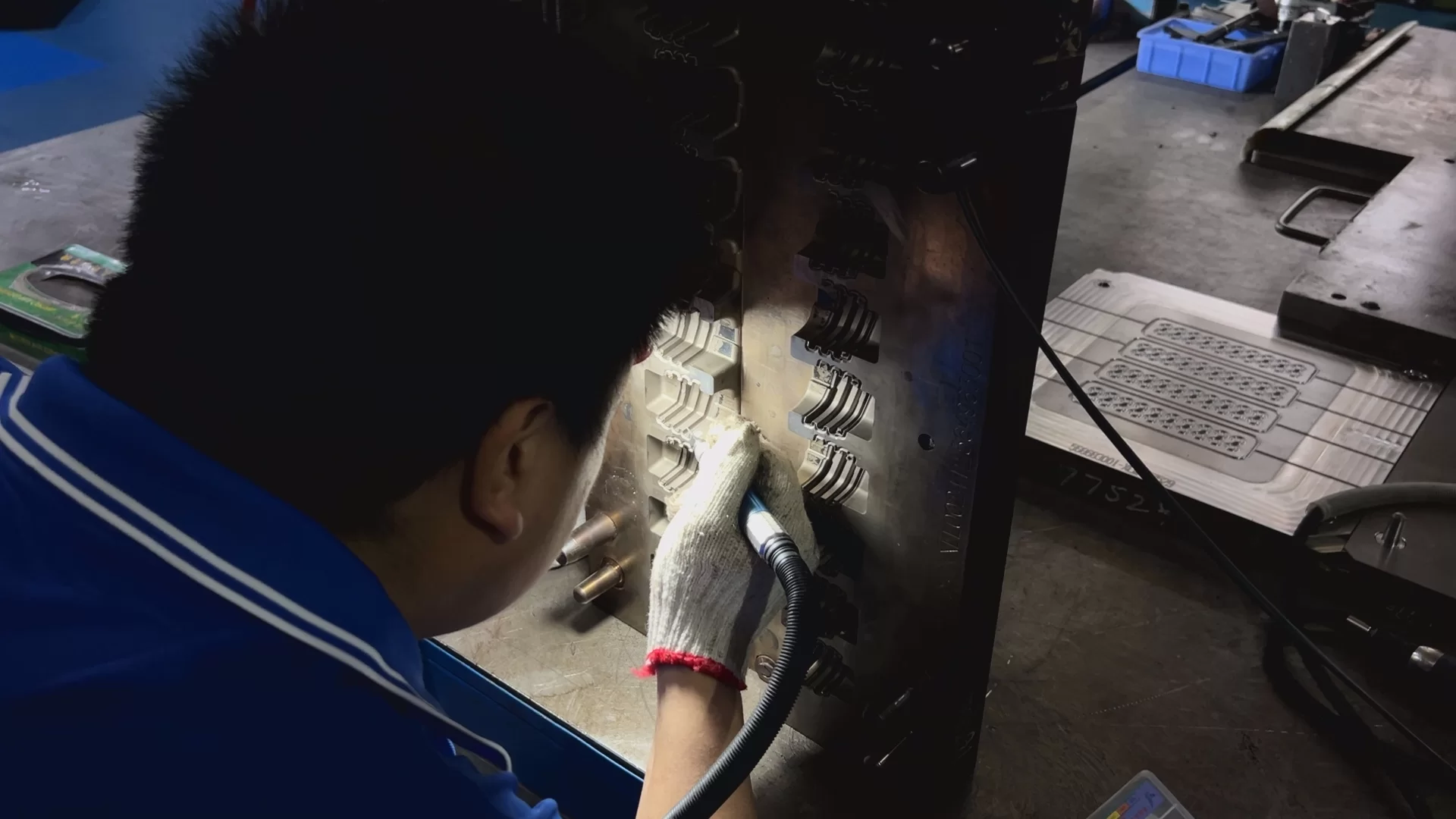

Every machining process is governed by detailed operational standards and monitoring protocols, ensuring quality control at every stage.

Select Language

Select Language